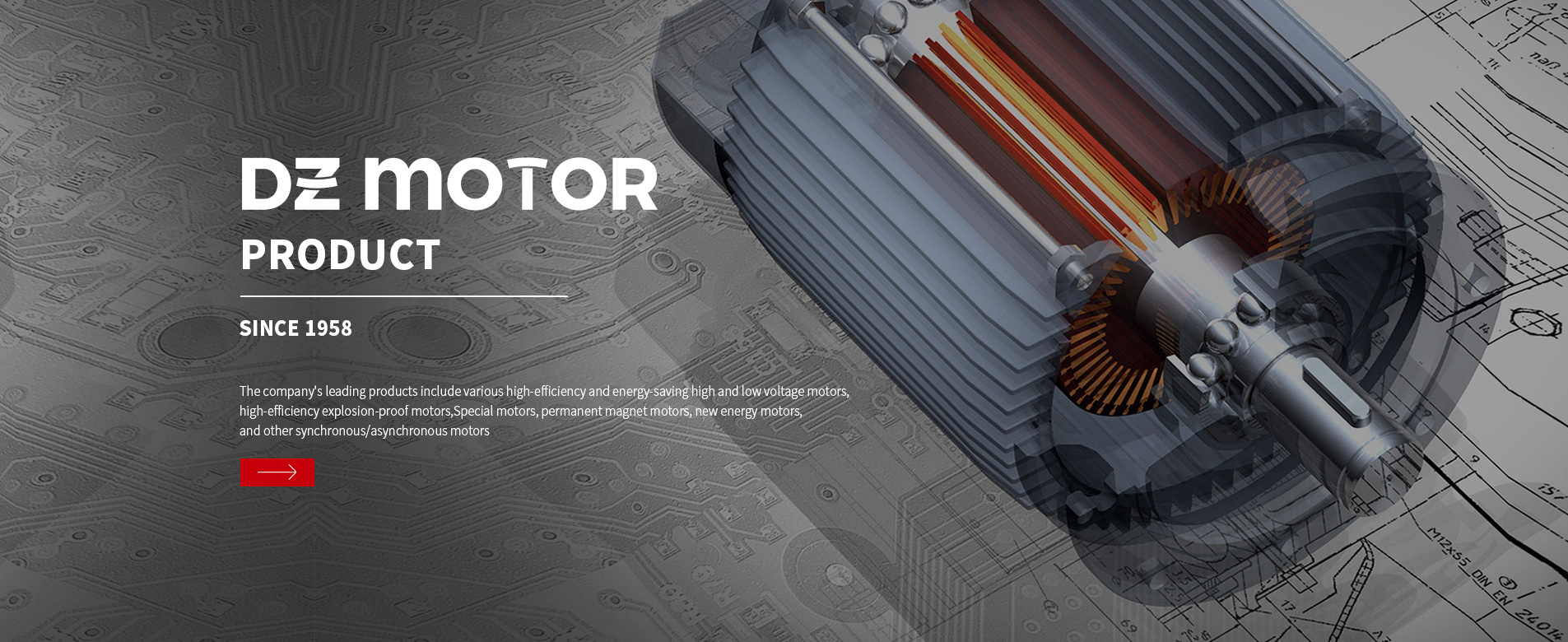

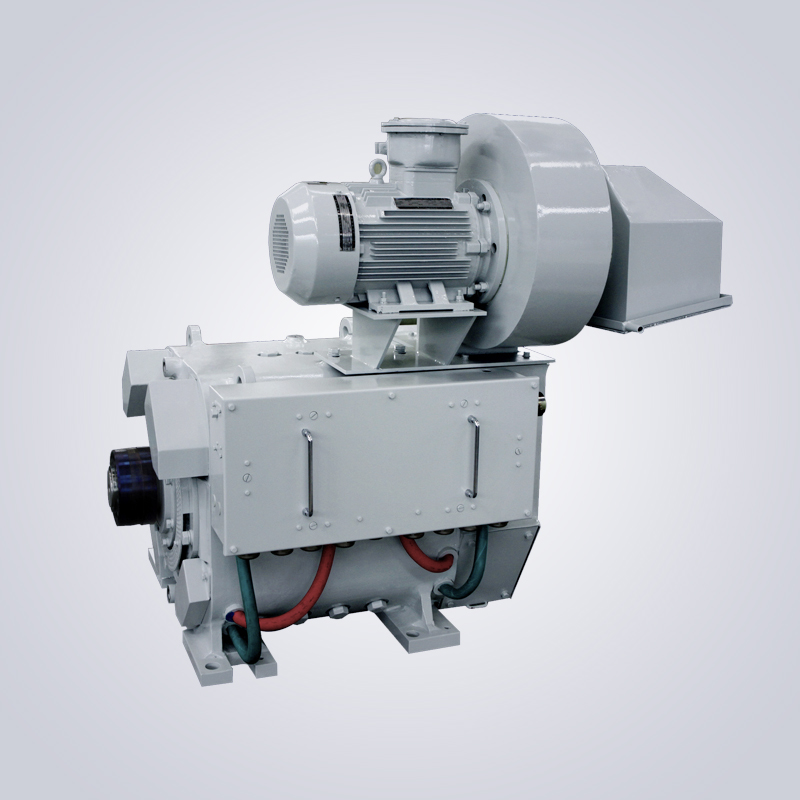

The ZZJ-800 series rolling mill auxiliary drive motor is our company's main product, manufactured in accordance with the national standard of "Rolling Mill Auxiliary Drive Motor". It is an important power equipment in the steel industry. In harsh working environments, it can withstand frequent starting, frequent reversible braking, and repeated large overload torque. It is mainly used on equipment such as work roller tables, screwdown devices, loop tension rollers, shear machines, clamp cranes, etc.

Learn More

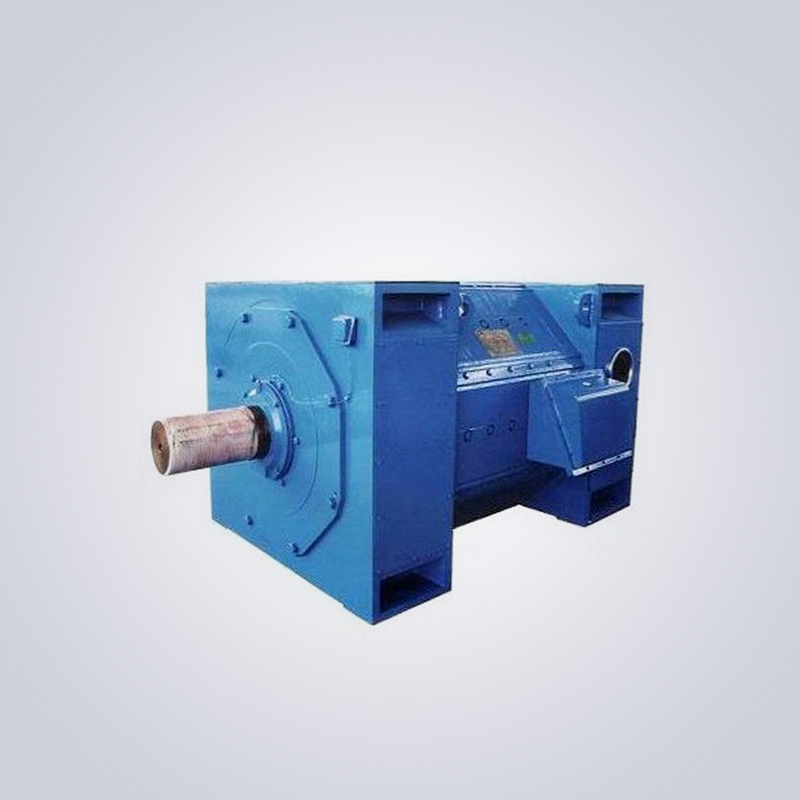

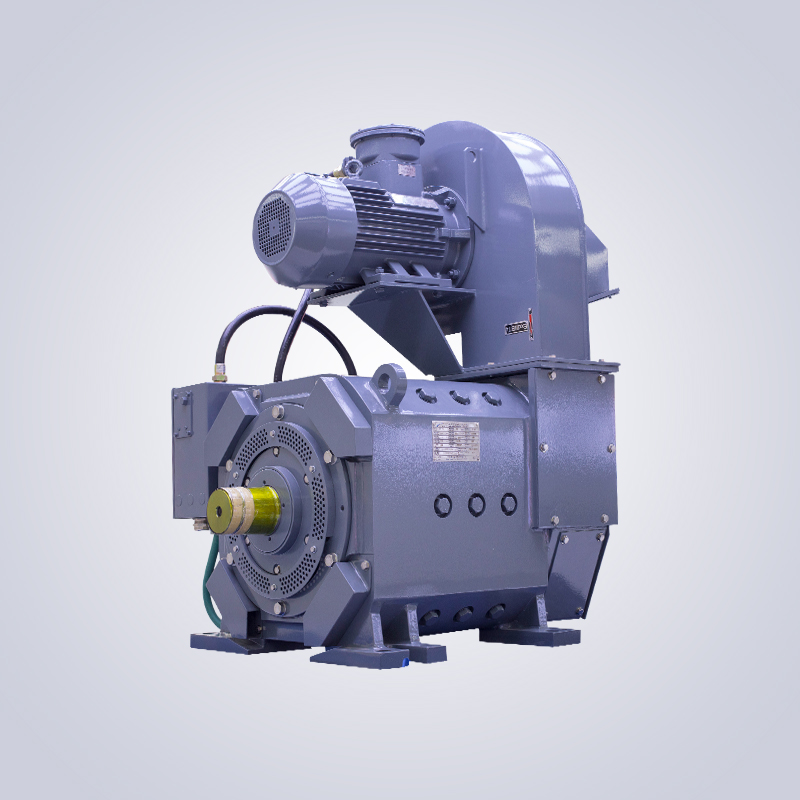

The ZFQZ series DC motor is a series of products developed on the basis of the Z4 series DC motor and drawing on the main technology of the ZZJ-800 series DC motor. The rotational inertia of the motor is 45% and 65% of that of the ZZJ-800 series and ZZJ-900 series, respectively, adapting to harsh working conditions of frequent forward and reverse rotation and frequent starting and braking. The motor has excellent overload characteristics, with its maximum torque and starting torque being 112% and 117% of the ZZJ-800 series and ZZJ-900 series, respectively. The weight of the motor is only 65% of the ZZJ-800 series. The power level of the motor meets the international standard of IEC34-13 "Technical Specification for Auxiliary Motors for Hoisting and Metallurgy". The external dimensions of the motor are in addition to the axial size between the two foot holes; B" In addition, all comply with the IEC72 international standard. The motor can achieve the main installation dimensions consistent with the ZZJ-800 and ZZJ-900 series through a bottom plate, and the corresponding shaft extension dimensions of the ZZJ-800 and ZZJ-900 series can be negotiated, thus replacing the ZZJ-800 and ZZJ-900 series products.

Learn More

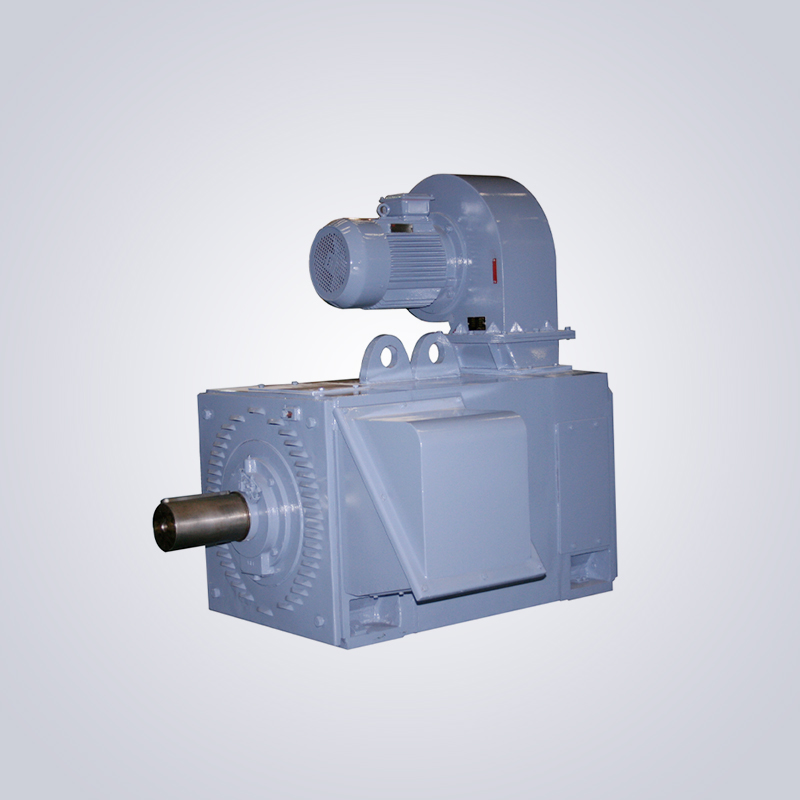

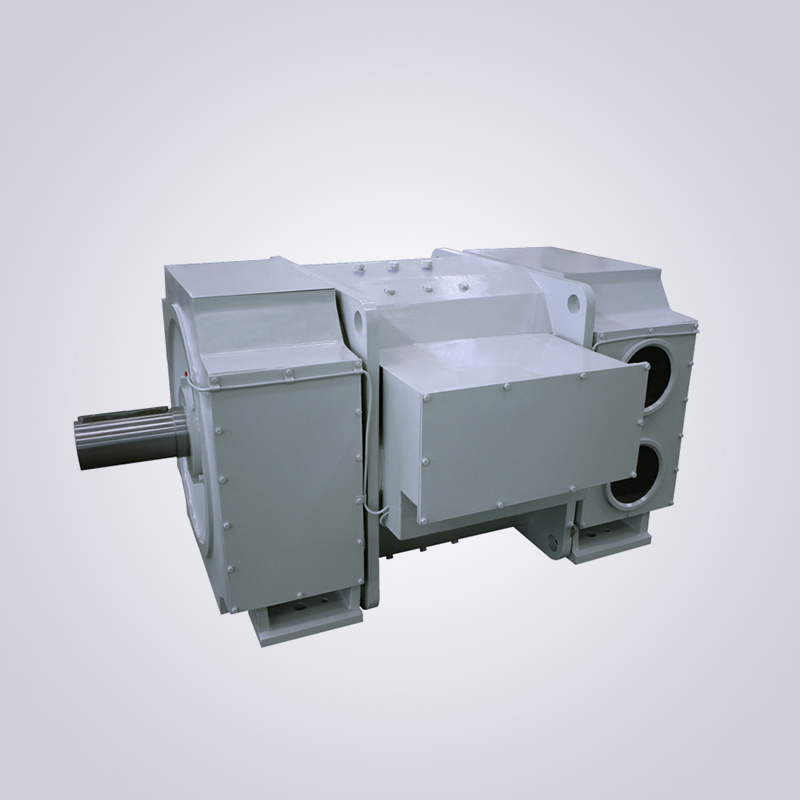

The Z710 DC motor is a newly developed Z-series DC motor by our company, with a center height of 710 millimeters. Due to its unique structure and performance, the Z710 motor is somewhat different from the Z-series medium-sized DC motor. The base of this motor adopts a polygonal laminated structure, which has the advantages of small size and light weight. It is suitable for thyristor rectifier power supply. The insulation level of the motor is F grade. The motor adopts solvent free paint vacuum pressure impregnation (VPI) treatment, which makes the winding insulation have good moisture resistance, mechanical strength, and excellent thermal conductivity. The armature iron core is stacked with silicon steel sheets, which has good magnetic conductivity. The motor adopts rolling bearings, Stable operation.

Learn More

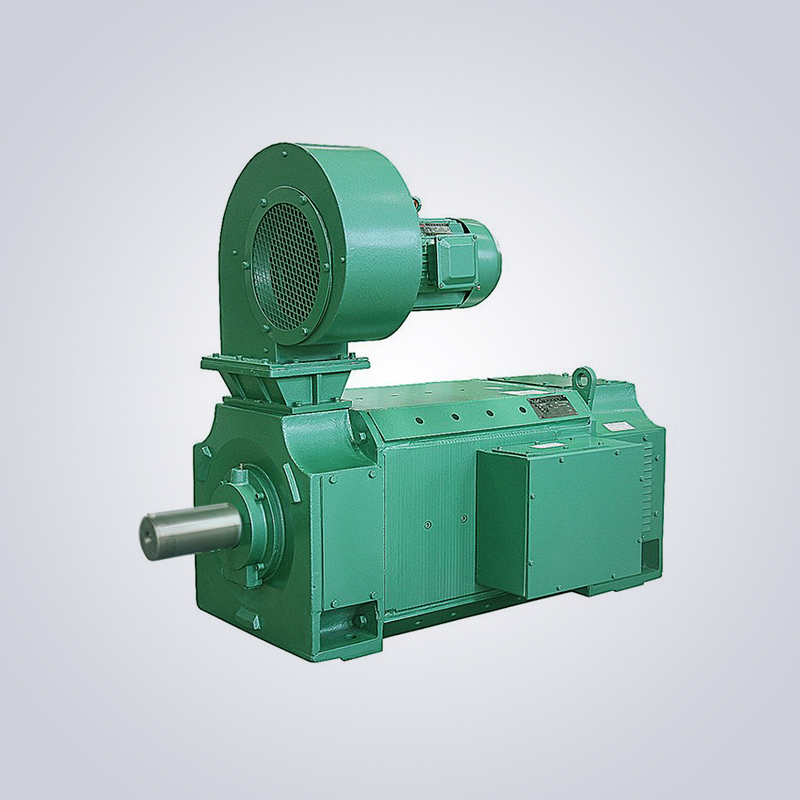

The DC motor in the Z series is an updated product developed by our company. Adopting a new design, it has the characteristics of high output power, low noise, low vibration, high efficiency, high reliability, and good safety performance. The performance, appearance, installation dimensions, and technical requirements of this series of motors comply with the standards (GB) and the International Electrotechnical Commission (IEC). The mechanical dimensions and tolerances of each part of the motor comply with the International Committee for Standardization (ISO) standards.

Learn More

The Z4 series DC motor adopts a new design, which has the characteristics of small size, small moment of inertia, light weight, high output power, high efficiency, high reliability, and good safety performance. It has excellent dynamic performance compared to the Z2 and Z3 series motors, More suitable for use as a power source and executing motor in control systems that require smooth adjustment, automatic speed stabilization, and sensitive response.

Learn More

This motor can be used as a DC motor to rotate the mud pump motor, rotary table motor, or winch motor of a drilling rig.

Learn More

This motor can be used as a DC motor to rotate the mud pump motor, rotary table motor, or winch motor of a drilling rig.

Learn More

The HZJ series DC motor is a high-power DC motor developed for petroleum electric drive drilling rigs. The motor adopts internationally advanced motor manufacturing technology and the main pole coil is hot pressed. Advanced mechanisms such as frame steel plate compression welding, steering gear spiral groove, oblique brush holder, and steel wire binding. The main characteristics of the motor are: positive pressure explosion-proof, high current, high torque, wide range of constant power speed regulation, good universality, maintenance free, high efficiency, and high reliability. Its external installation dimensions are the same as those of foreign DC drilling machines and can replace imported drilling motors. This motor can be used as a DC motor to rotate the mud pump motor, rotary table motor, or winch motor of a drilling rig.

Learn More